A few months ago, StangTV began giving the renowned Formula Drift hot shoe Justin Pawlak a hand building up his 2006 Ford Mustang GT. For this project, which we have dubbed sidewayS197, we plan on putting a stock S197 through some changes in order to create a street performing Mustang that Pawlak can easily toss sideways and turn rubber into smoke. To achieve our goals we need to improve our Mustang suspension performance, we’ve turned to BMR Suspension.

A few months ago, StangTV began giving the renowned Formula Drift hot shoe Justin Pawlak a hand building up his 2006 Ford Mustang GT. For this project, which we have dubbed sidewayS197, we plan on putting a stock S197 through some changes in order to create a street performing Mustang that Pawlak can easily toss sideways and turn rubber into smoke. To achieve our goals we need to improve our Mustang suspension performance, we’ve turned to BMR Suspension.

Pounds Lost and Tools To Have

Weight Saved

- Total of all four BMR parts – 29 lbs.

Tools Needed

- Standard and Metric Wrenches

- Standard and Metric Sockets (regular and deep)

- 3/8-inch Drive Ratchet

- Hydraulic Jack and Stands

Our first steps with Project sidewayS197, were to stabilize the front suspension a bit with the addition of a ROUSH Performance front anti-sway bar package and a ROUSH Mustang exhaust.

In this chapter of the sidewayS197 saga, we’ll look at further improving the performance of the front suspension through a system of parts and pieces that are available from BMR Suspension. This will tie together and tighten up the front end of the car, and improve its steering and control characteristics. While all of these front end components are available separately, using them together is best, since the sum of the parts work as a system, elevating and improving the overall performance of each of the parts.

The BMR radiator support, A-arm support, and chassis brace sit beside the much heavier OE radiator support (top). The BMR tubular radiator support (lower left) bolts right up to the OE mounting locations, and offers much sturdier anti-sway bar mounts. BMR's tubular K-member (lower right) can drop the engine as much as 1.25-inches.

The BMR system we installed consisted of four integrated parts. First and foremost was the BMR K-member (part number KM011), followed by a BMR A-Arm support brace (part number AAS001), BMR Chassis Brace (part number CB004), and BMR Radiator Support (part number RS003). Each came with all the mounting hardware needed. We talked to Kelly Aiken, S197 Mustang Suspension Specialist at BMR to get more details on the parts that make up this system.

Our K-member saves weight, yet has the strength to handle hard street and track use. – Kelly Aiken, BMR

Aiken also explained, “One of the S197’s issues is that the shifter is body-mounted so any time you have drivetrain deflection such as during hard cornering or lots of frame flex under hard acceleration on a drag strip, there can be missed shifts at high RPM. There are torque limiters to help solve this problem, but with our K-member, you don’t need a torque limiter.”

“Our K-member saves weight, yet has the strength to handle hard street and track use. It is 22 pounds lighter than the factory unit. In addition to weight savings, it also provides the Mustang owner a unique BMR engine-mount design, with a wafer-like pancake poly bushing that’s designed to inhibit deflection of the drivetrain significantly, Aiken said.”

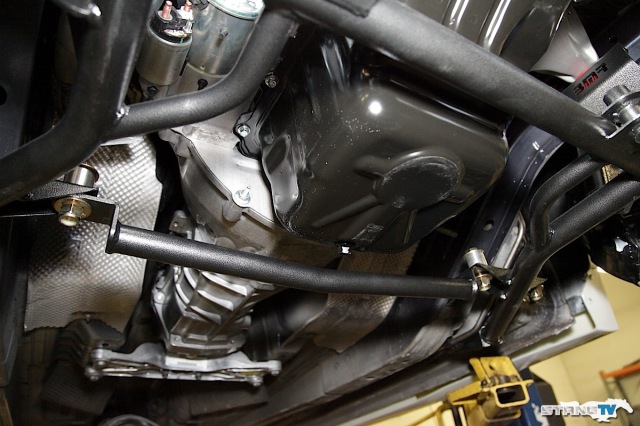

Size, weight, and rigidity alone are not the only advantages the BMR K-member (above) offers over the OE K-member (below), it also provides much easier service access.

We discovered another significant aspect of the BMR K-member. Not only was our specific part designed to drop the engine a 1/2-inch, which lowers the cars’ center of gravity, but all BMR K-members are designed to go down another 3/4-inch by removing the upper mount on the K-member. The upper bushings can be eliminated to give an overall drop of 1.25 inches to the engine. Aiken told us, “The average driver may not feel the handling improvement from the engine drop, but a serious road racer or drifter will.”

The other great benefit of the BMR K-member is that it allows you to raise or lower the steering rack. You can trim down tabs or add shims, so essentially you can adjust bump steer by moving the rack up or down. You can’t do that with an OE K-member. Ease of service is sort of a side benefit, but hey, we’ll take it. With a tubular K-member replacing the huge OE K-member, working on the car’s underside (such as dropping the oil pan) is much easier, and that’s a huge advantage.

Key installation points on the BMR K-member to know ahead of time, are that the tires and wheels must be removed, and the tie-rods have to be loosened from the spindles. The steering shaft cross-bolt must be taken out so the rack can be moved out of the way to allow access to the A-arms. The factory K-member/A-arm assembly is removed, of course.

Our chassis brace pulls the whole system together and really makes the difference.

A-Arm Attention

The primary purpose of the BMR A-arm support is that due to the K-member and A-arm design of the S197 cars, there is a lot of load on the rear A-arm mount under heavy braking. On the 2000-model year and newer Mustangs, Ford decided to put in an A-arm brace for a good reason, to stabilize the rear leg of the A-arm. That rear leg is the weakest point on the A-arm.

The BMR A-arm support is easy to install and provides a sturdy brace to help keep severe braking forces from damaging the A-arm’s rear leg mounts.

When you go into a heavy braking situation, the force is trying to rip that inner A-arm mount loose and wants to fold that rear leg in, so if you have a bar bracing those two points it keeps it from folding or tearing. The BMR A-arm replaces this OE brace to provide a more rigid support between the two inner control arm mounts.

Aiken said, “I tell guys that are drag racing that they don’t really need it because they’re not usually doing hard braking and putting a lot of force on those rear A-arm mounts, especially if they’re slowing down on skinny 3.5-inch wide tires. However, for anybody using fat tires on the front end, they really do need a brace there. That is especially true for the street or road racing because of the lateral forces placed on the front end. When you slam on the brakes, it wants to rip that rear A-arm mount loose.”

The A-arm support from BMR was an easy install. It gets mounted to the car’s underside between the two rear A-arm mounts on the K-member. The BMR A-arm Support spans the distance between the two rear A-arm mounting points and provides a rigid tie in a place where additional bracing is of utmost importance for a car that will see increased loads on the chassis and subframe.

The BMR chassis brace ties the entire system together and helps to stiffen up the car’s front subframe.

It’s worth noting that since this car is a drifter we didn’t go with BMR’s A-Arms. JTP actually has as custom built arm and spindle through his Hotline Performance shop that give the car more steering angle. Since JTP had the arms already covered, there was no need to use BMR’s arms for this install.

Rigid Support

One look at the BMR Radiator Support and it’s easy to see that this is an awesome piece of engineering. It does a number of things very well. It replaces the heavy, stamped, OE radiator support and shaves seven pounds off the front end of the car. While this may not seem like a lot taken on its own, remember that it’s losing weight in a very critical section of the car. The BMR Radiator Support also allows a 2005 to 2010 Mustangs to utilize the Z-bracing system that the 2011-and-up cars have.

The design and increased rigidity of the BMR Radiator Support also allows the use of most of the sturdier aftermarket anti-sway bar saddles. Aiken chimed in on this particular piece that BMR is extremely proud of, “Our radiator support is all one piece of formed steel plate.”

A front view of the completed installation shows how the four pieces of BMR equipment all tie together to form an extremely sturdy support system.

Installation of the BMR Radiator Support first requires the removal of all the lower plastic panels covering the OE chassis brace and radiator support to allow access. The OE chassis brace was then removed. To get to the OE radiator support, the anti-sway bar mounting bolts must be removed so the bar can hang freely by the end links. Then the radiator support bolts can be removed and the support dropped. The radiator will hang unsupported by its hoses and the AC lines.

The OE radiator support mounting bushings are retained and re-installed on the new BMR support, and then the BMR unit is bolted into place using the OE mounting hardware and locations. Once the BMR Radiator Support is in place, the anti-sway bar can be mounted to the bracket locations on the new support.

This rear view of the BMR front end system shows the tie-in between the A-arm brace and the A-arm mounts on the K-member.

Since replaced the OE chassis brace with the BMR Chassis Brace, we tossed the OE brace instead of re-installing it. The front of the BMR chassis brace ties in to the BMR Radiator Support, the rear of the BMR chassis brace bolts to the steering rack mounting bolts. The plastic covers previously removed can be discarded or trimmed to clear the new BMR Chassis Brace and re-installed.

One of the greatest benefits to installation of the BMR Radiator Support is that it allows you to use BMR’s upgraded chassis support. According to Aiken, the radiator support is very rigid, but when tied together with the BMR Chassis Brace it makes the subframe a whole lot stronger.

It stiffened up the front end quite a bit, and the car felt much better planted. – Justin Pawlak

Now that Project Sideways197 had received an entire front end support and bracing system from BMR Suspension that included a BMR K-member, BMR A-Arm Support, BMR Radiator Support, and BMR Chassis Brace, it was easy to see how much improved it was over the OE set up. All that was left to do was re-install the A-arms, tires and wheels, tie rod ends, and button it all up again.

Another advantage to the BMR K-member is the ability to move the height of the steering rack to adjust bump steer, something the OE K-member does’t allow.

The weight reduction and additional support and bracing offered by the highly rigid BMR tubular components will go a long way to improve the overall handling performance of the 2006 Ford Mustang. Justin Pawlak took the pony car out and after a good spin, said, “It stiffened up the front end quite a bit, and the car felt much better planted.”

Stay tuned to StangTV for more modifications and improvements to Project Sideways197, and further commentary from superstar Formula D driver Justin Pawlak as he continues to take the completely re-vamped Mustang GT out on the blacktop and put it through its paces.