With the increasing availability of “power adder” options coming online for the Ford Coyote Gens I-III, a total system approach is necessary to make sure you’re not leaving untapped horsepower on the proverbial table. Case in point, the Gen III Coyote engine available in the 2018 and newer Mustang is a solid base engine from which four-digit power numbers can be extracted. In “Boosted Coyote; Bringing the Short-Block to Life with Livernois,” noted engine builder Fonzie Novelo of Livernois Motorsports confirms, “we have yet to find a limit on power on these [OEM] short-blocks in the real world, so we’re comfortable with saying 1,200 horsepower [at the crank].”

To access that hidden power, a myriad of enhanced parts will need to be employed, first, in hopes of keeping the engine operating as intended. Secondly, the parts will need to be of the sort that enhance the volumetric efficiency of the system. That’s all well and good, but if the supporting components outside of the engine aren’t able to feed the engine properly, your Coyote won’t howl.

Keep It Basic

For this reason, we’ll dive into the theories behind fuel pressure and fuel pump voltage and how they can support or prevent any engine from reaching its full potential. Without backing up too many steps, we should remember that any engine is simply an air pump. Just as simply, the more air we can pump through an engine, the more power (and work) we can extract from it. When a naturally aspirated engine revolves twice (think 4-stroke engine), it pumps the piston-swept volume of air through its system (let’s ignore expansion due to exhaust heat, just to keep things simple). So, a 5.0L naturally aspirated Coyote engine would pump 5.0L of air for every two revolutions.

If that same engine were blown at 1 bar (14.7psi), it’s now being force fed air at twice the pressure as previous (atmosphere is already 14.7psi). This means that more air molecules are being crammed into each cylinder during each revolution, and ultimately more air molecules have been pumped through the engine during those same two revolutions (again for simplicity, ignore pumping losses and assume peak torque).

More air passing through the engine is great, as long as the increased air is met with an increased volume of fuel being delivered (remember, we always need to balance air/fuel ratios). Before moving on to that increased fuel volume, we must consider the “pressure battle” being undertaken by the injector. [For the comprehensive explanation of effective pressure across the fuel injector from fuel rail to outlet, Brian Havin’s “Under Pressure: How a Fuel Pressure Regulator Works with Boost” article does a great job of explaining how fuel pressure regulators compensate for boost.]

In a naturally aspirated system there may be a vacuum (or reduced positive pressure) on the outlet side of the injector effectively pulling fuel out of the injector. In a boosted system, there is some pressure already present at the injector outlet, meaning the “effective pressure” across the injector is the fuel rail pressure minus the pressure on the outlet side of the injector. In the case of a port injector (PI), boosted pressures could be 5 to 25 psi, or higher. If the rail pressure is 55 psi, the effective pressure across the injector would be between 30 and 50 psi. This phenomenon is exacerbated in a system such as the Gen III Coyote engine, where direct injection (DI) injectors are attempting to overcome in-cylinder pressures, which can far exceed typical manifold boost pressures.

Understanding fuel pump flow at increased pressure is crucial to properly supplying your Coyote with enough go-juice.

Remember, the goal is to provide enough extra fuel volume to compensate for the increased air/oxygen molecules entering each cylinder and maintain target air/fuel ratios. While some changes can be made to injector pulse width to remain open a little longer and dump additional fuel, this solution has its limitations. So, the challenge is to force a larger volume of fluid through the same cross-sectional area, in roughly the same time (or reduced time, as RPM increases).

To gain a better understanding of the relationship between fuel pressure, pump voltage, and delivered volume, imagine a fuel pump. The pump receives fuel from a low-pressure source (tank for example), does work on the fuel, and ejects the fuel at a higher pressure. Similarly, a battery receives charge at a low voltage and ejects charge at a higher voltage after performing work. Also analogous, electrical current and fluid flow can both be looked at as a “pipe” through which either fluid or electrical current flow. So, voltage and current may be looked at together as a pipe with fluid flowing through it; the size of the pipe determining the current/flow, and voltage/pressure determining how hard the fluid is being pushed through the pipe.

Let’s return to the example of injectors in naturally aspirated and supercharged systems. In the blown example, higher pressure exists on the discharge side of the injector (in the cylinder or manifold) due to the forced induction system compressing more air molecules into the manifold/cylinder. So, the effective pressure differential (or push) across the injector is lower (think pressure in – pressure out). Comparing the two examples, you should expect to push less fuel volume through the injector in the blown system. This can be overcome using at least three methods; using a rising rate pressure regulator, increasing fuel pump voltage (push), and adding new/additional fuel pumps. Some limitations do exist, as a variable pressure regulator can only increase fuel pressure as high as the fuel pump is able to supply, while fuel pump voltage also has its limits due to the physical construction of the electric fuel pump (i.e. you can only apply so much voltage before failure occurs).

In his article “Boosted Coyote Pt 4: The Livernois Long-Block Hits the Dyno,” Greg Acosta illustrates the challenge of supplying a thirsty Gen II Coyote with enough fuel for high boost/power applications. Even after upgrading to 1500cc/min injectors, the Coyote came up short of their ultimate power goals due to the fuel pump being unable to keep up. Granted, this project was run on E85, which tuner Sai Li points out “usually needs about 30 percent more fuel (volume) than 93 octane.” The likelihood of this being an issue in the real world is measurable. Additionally, the Coyote in Acosta’s article is a Gen II unit, which doesn’t factor in the higher DI pressures that exist in the Gen III.

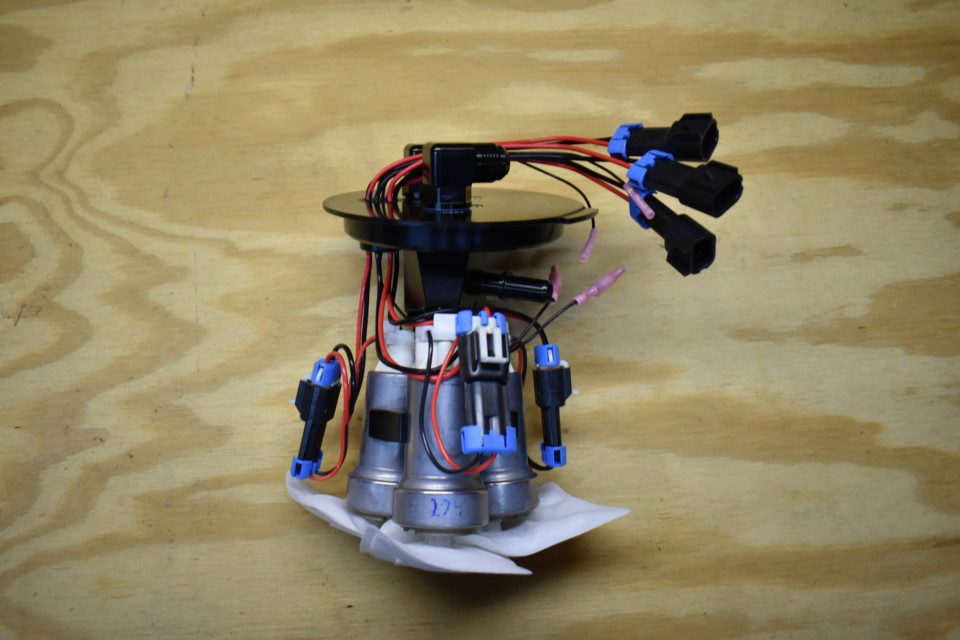

To overcome the lack of volume, “Boosted Coyote Pt 5: Adding Fuel to the Fire with Deatschwerks” illustrates the use of the Fore Innovations S550 Triple Pump Module, which effectively “switches” on a third fuel pump based on a pressure signal from the intake manifold. So when high boost was present, a third fuel pump was employed. But under standard “around town” driving conditions, the third pump remains inactive. Cool solution, yes. But cost effective for the average Joe trying to squeak out a few more ponies from stock or average upgrade parts? Not so much.

What Are My Options?

So what is the average Joe to do about pushing fuel a little harder through their fuel system? The aftermarket has Joe’s back and numerous options exist for voltage boosters/amplifiers intended to bring additional volume output to otherwise “tapped” fuel pumps. To accomplish the task of more volume, this type of method increases the voltage of the fuel pump, which increases the output pressure of the pump. Remember, pressure (analogous to voltage) is the push we’re trying to increase through the fuel system leading to the cylinders.

One such example is the Kenne Bell Boost-A-Pump. Simple to install, it only requires splicing a single wire and grounding a second. Having used this unit in the past, Jhame Peters of CES Motorsports in Newbury Park, CA pointed out that “a unit like this is nice because it is simple to install and start tuning with and (the Competition model) provides a linear voltage output in relation to manifold boost pressure.” JMS and MSD both offer their own fuel pump voltage boosters, which have adjustable ramp rates. Boosted voltage tuning is possible with a stock fuel pump, but Peters warns that “nobody knows what durability and longevity impacts increased voltage will have on a stock pump. They just aren’t tested that way. If you’re pushing a stock unit hard enough, one hiccup and you may be in a world of hurt.”

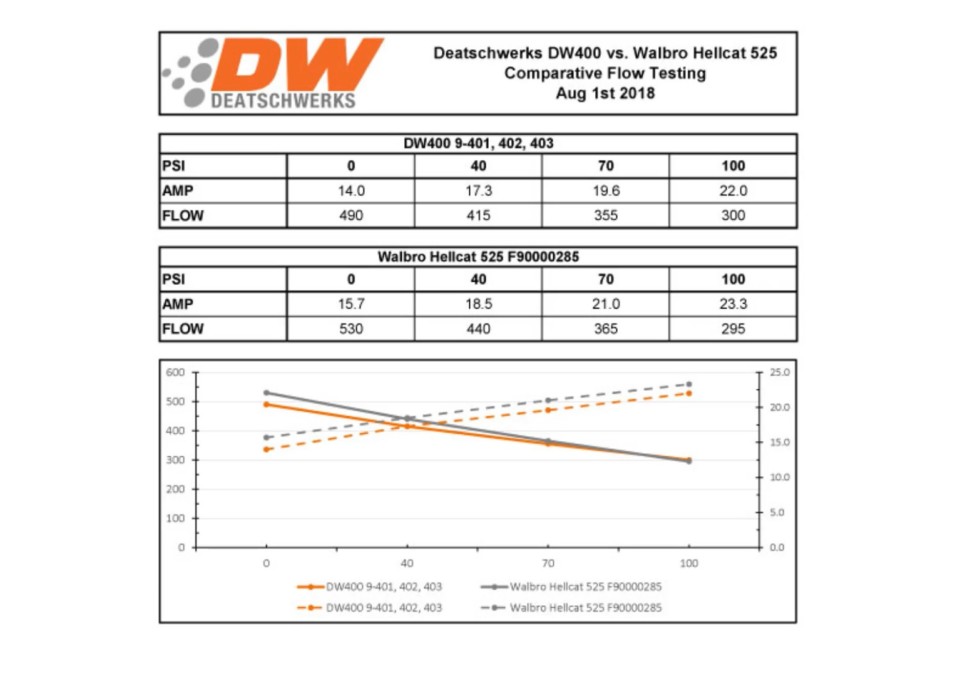

Peters encourages anybody looking for added fuel pump output to know their system demands first. If they are operating within a reasonable safety margin, in excess of intended pump output, a booster may be all that’s needed. But if system demands commonly look for significantly more than stock volume, start looking to DeatschWerks for a more appropriate pump. David Deatsch confirms, saying, “most DW pumps are rated to 18 volts. Some of the smaller format compact pumps are only rated to 16 volts, and the larger format DW400 is rated to 20 volts. Check your pump’s technical data sheet for specific value. The max suggested voltage is for intermittent use only (i.e. voltage booster on a Hobbs switch).”

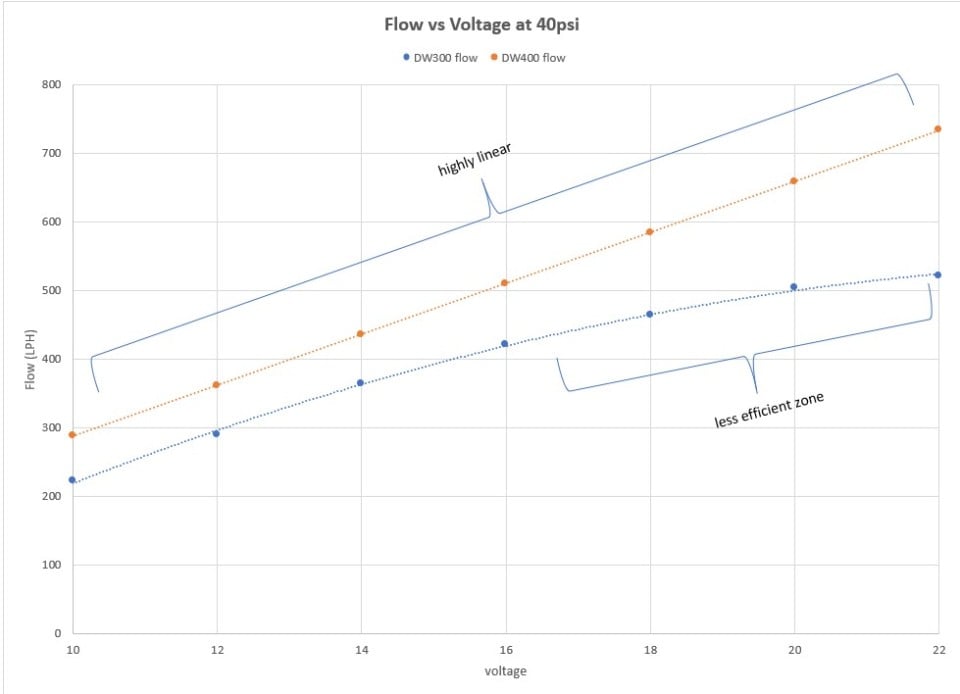

Beyond just knowing how much voltage your pump can accept, it’s important to understand what fuel volume that increased voltage will result in. DeatschWerks has already done the research in determining flow with varied voltage. The chart below compares the flow of the DW300 and DW400 pumps, both tested at 40psi with varied voltage. This chart highlights the importance of properly sizing your fuel pump so as not to always be requesting maximum output. Deatsch points out that “the correlation between voltage and flow increase is linear, but only within the pump’s efficiency range. Once outside of this range, gains in flow for each volt applied diminishes, and the pump starts to overheat, damaging the brushes and armature.”

That detail can be a crucial factor when choosing a pump. As an example, if an engine would frequently be seeing demand close to 500lph, choosing the DW400 would help drop the required voltage and would allow the pump to operate in a more efficient range (for example, just because the DW300 can flow 500lph, that doesn’t mean that’s the best choice). If unclear of the fuel volume demands of your engine, pop over to the Fuel Calculators page on the DeatschWerks website, where multiple calculators can help you estimate pump, injector, and even flow versus pressure.

An important feature of many voltage boosters is the ability to dynamically vary voltage based on system demand. More simply, this means only increasing fuel pump voltage when increased fuel volume is necessary. Deatsch stresses that “variable increased voltage is by far the best solution. This is especially true for street driven cars. Increased voltage equals increased heat and increased wear on the brushes and commutators of any DC brushed fuel pump. Variable voltage will not only decrease the wear on the fuel pump, but also lower fuel temps. Running the pump constantly at high voltage will introduce more heat to the fuel system, and over long periods of time, may cause issues with vapor lock or boiling fuel.” Commonly available “Boost-A-Pump” style amplifiers can receive varied input signals such as boost switches (aka Hobbs) and RPM. Using these types of feedback loops can help keep that pump out of the red zone when unwarranted.

Future Tech (Is Here)

Those looking to further increase the capability of their machines, or those who may always be demanding the most out of their pump, may also look towards DeatschWerks’ brushless line of fuel pumps. DC Brushless motors are about 90% efficient while brushed motors are about 75% efficient. This inherent efficiency advantage translates to DC brushless motors responding very favorably to increased voltage. In addition, since brushless motors do not have commutators or brushes, they won’t overheat and “burn up” when subjected to increased voltages. The DW Brushless in-tank pump is a great candidate for voltage boosters.

The Long and the Short Of It

Understanding total system demands of a high-performance engine includes looking at the peripheral components that will supply your machine with what it needs. Understanding how those components work with the rest of the system will help optimize not only performance, but durability. Similar to asking an engine for increased output, a fuel pump may just be waiting for a little encouragement to help push your Coyote to new heights.