A key factor in the “turnology” of any road course vehicle is the connection between the driver and the front wheels. The ability to promptly and precisely transfer driver input to the steering box is of paramount importance — especially if the car is to be autocrossed or road raced.

The first question to address is whether or not power steering should be employed. There are certainly those who eschew power steering and profess that not having an assist gives them a better “feel” of the track. But, conventional wisdom dictates that the heavier the car and the bigger the tire, the more force will be required to turn the steering wheel. Unlike a sophisticated video simulator, you simply can’t turn a dial and adjust the FFB (force feedback). At some point, the physical factors and the time behind the wheel can collectively wear you out — even though our old pal Archimedes would offer a partial solution in the form of a larger diameter steering wheel.

For myriad reasons, T-Rex was fitted with a 20:1 power rack and pinion setup from Detroit Speed. While a quicker 15:1 ratio (the relationship between input motion and output motion in degrees) was available, the fact that T-Rex will also be participating in top speed related events like NHRA drag races, SCTA dry lakes, and perhaps Bonneville, the 20:1 ratio was deemed appropriate.

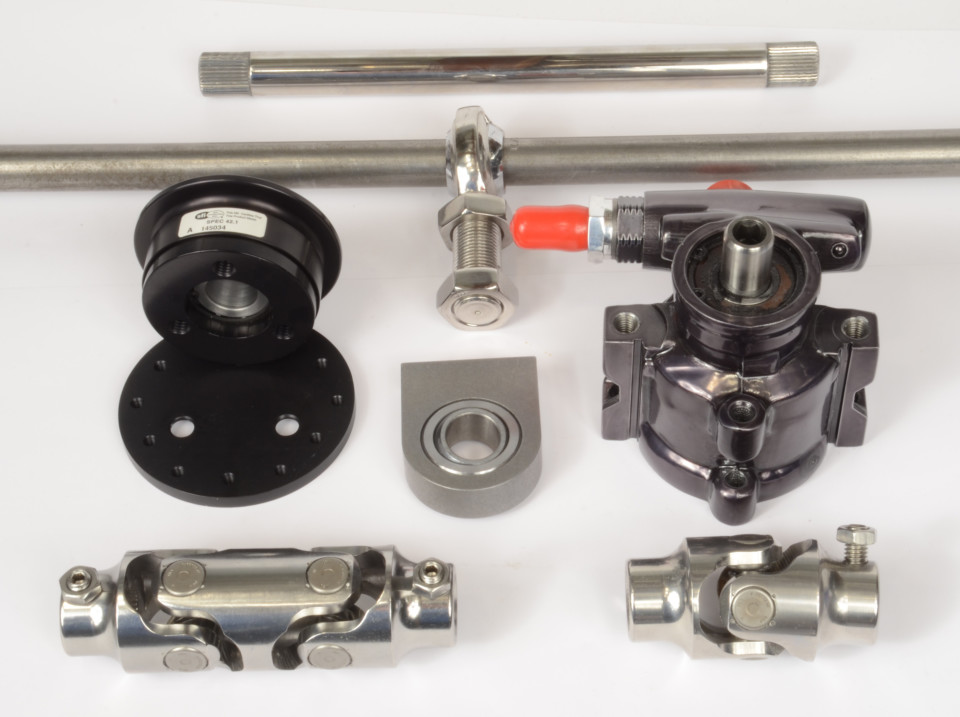

The system consists of Borgeson ¾-inch shafts, supports, single and double U-joints, plus an SFI 42.1-approved quick-release hub from Jegs and a polished and black anodized power-steering pump from Tuff Stuff.

Of course, the “power” for the power steering unit has to come from somewhere, and since a lack of space ruled out the OEM Coyote unit, the aftermarket came to the rescue in the form of a compact “Type II” Saginaw-style pump from Tuff Stuff. This little gem puts out the required 1,200 psi, 3 gpm flow, comes with AN-6 and AN-10 fittings, and has a “black chrome” finish.

Art Morrison Enterprises has built this “steering rack dyno” to measure rack performance and driver feedback. Using it, AME has developed flow control valves that overcome the “mushy” feeling common to many power steering setups.

The folks at Art Morrison Enterprises have created a “steering dyno” that is used to test racks and measure their “feel.” They’ve determined that, to obtain tactility more in line with contemporary sports cars than a ‘70s muscle car, reducing the fluid flow to 2 gpm is beneficial. Accordingly, they’ve developed an in-line flow control valve for the tasks. This is especially important given the relative light weight and front/rear balance of T-Rex.

Fluid comes via a Moroso remote reservoir and XRP braided hose. A custom bracket was fabricated to mount the pump in the area formerly occupied by the Coyote’s alternator.

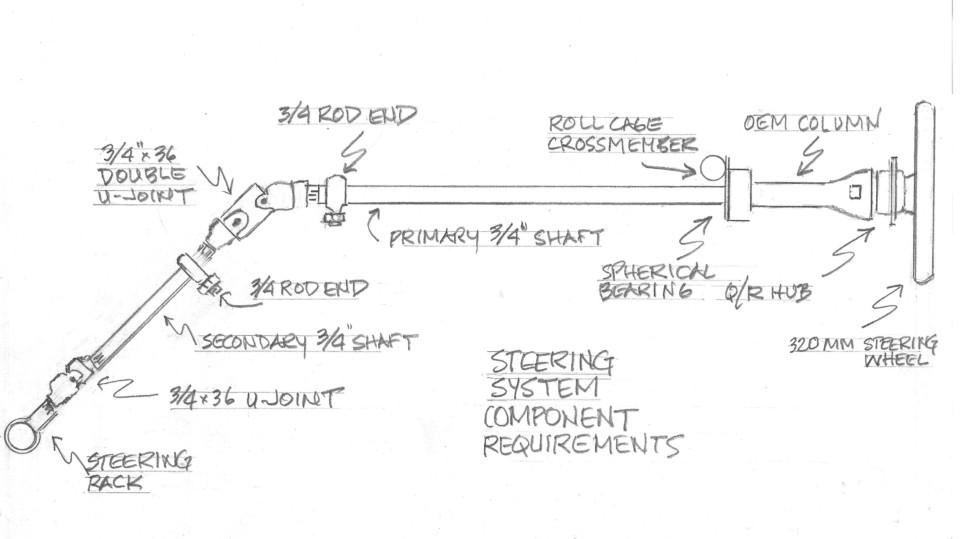

In planning a steering system, it’s helpful to sketch out which components will be utilized. From this starting point, the actual shaft lengths and pieces can be identified by Borgeson for easy ordering.

The next challenge was getting driver input to the steering rack, and the logical course of action was to plot everything out and determine what combination of components would best accomplish the routing. Fortunately, Borgeson Universal has been in the business of manufacturing steering universal joints and components for more than 100 years and has everything down to a science. Borgeson.com is an intuitive website that makes it relatively easy to wade through the maze of shaft sizes, spline counts, joints, and supports required to configure a system.

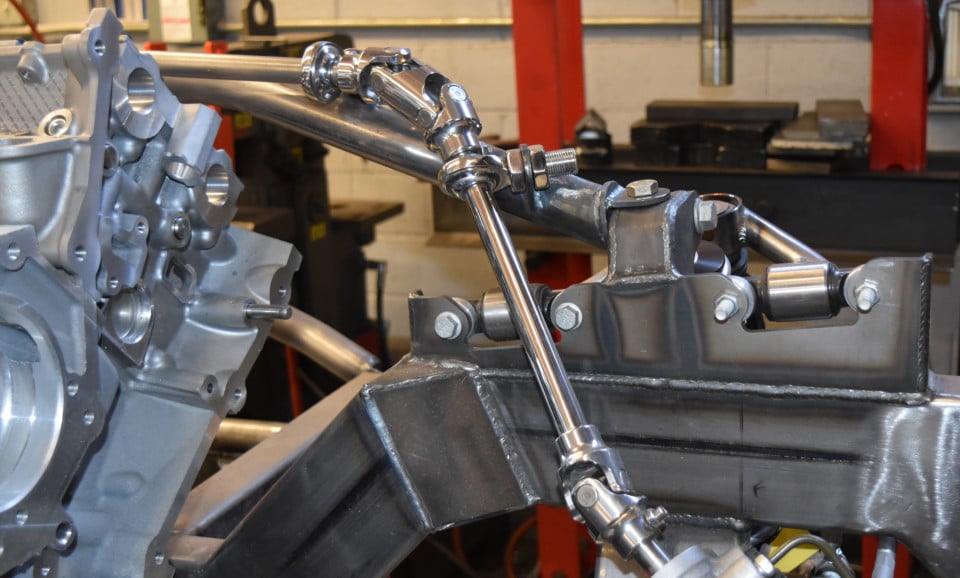

CBM’s John Schiess is shown measuring for the steering-linkage component length, with the complete assembly utilizing Borgeson ¾-inch polished stainless-steel components.

Needless to say, dropping a big Coyote V8 into the confines of the TVR’s engine bay necessitated ditching the OEM steering shaft route in favor of a slightly more circuitous one that accommodated the wide DOHC powerplant and its headers. That said, the original TVR steering column with turn indicator and high-beam levers was retained — albeit shortened and equipped with nylon bushings to properly support the ¾-inch diameter shaft.

Care was taken to ensure that the steering linkage is stable. Borgeson ¾-inch rod ends were employed on the primary and secondary shafts, with a spherical bearing used to anchor the shaft inside of the firewall.

Starting at the rack, a ¾-36 x ¾-36 polished stainless steel U-joint connected to a short 7-inch ¾-inch O.D. secondary shaft, with a double U-joint handling the offset and steep transition to a long horizontal primary shaft. Both a ¾-inch rod end and billet steel encapsulated ¾-inch I.D. spherical-bearing mount were employed to provide the necessary support. The shortened TVR column, which contains levers for the turn indicators and high beams, attaches to the bearing mount. A slotted tab is welded to the roll cage crossmember, which allows the steering column to be adjusted up or down in a 2-inch range.

A slotted bracket was used to anchor the ¾-inch billet steel shaft support, providing 2 inches of adjustability. The stock TVR column was shortened and secured to the support. A ring was added to the Jegs quick-release to facilitate gloved-hand operation.

The final part of the project was integrating a quick-release type hub and steering wheel into the equation. A sturdy Q/R hub that’s SFI 18.1 rated was sourced from Jegs, with a large ring employed to provide the necessary grip of the collar with gloved hands. A 320mm diameter faux-carbon-fiber steering wheel, a discontinued NRG model, came via Amazon.

While this article covers configuring the steering for a somewhat unique restomod TVR, the same basic products and procedures can apply to a wide range of street machines, hot rods, and kit cars. It’s important technology if you like to turn corners.

(Ed note: for previous articles on T-Rex, see the intro article here, or the chassis and suspension article here).