Dynojet has been a leader in dynamometer technology for a number of years. Tuners around the world rely on their equipment and technology to get results. At this year’s PRI show, Dynojet was showing off their next genearation of dynamometer control systems and software, the new DynoWare RT and PowerCore software.

The main DynoWare RT control module is designed to incorporate more data than ever into the Dynojet PowerCore software. This includes:

The main DynoWare RT control module is designed to incorporate more data than ever into the Dynojet PowerCore software. This includes:

- Two inductive RPM pickups .

- Two optical RPM inputs.

- Four Dynojet CAN inputs.

- Six DynoWare expansion ports.

- Two infrared temperature sensor inputs.

- Two atmospheric sensor inputs.

- Four independent 0-5 volt analog inputs.

All of this data can be monitored and shown in the PowerCore software. For all wheel drive dyno owners, the unit also has inputs for the links engagement system.

Dynojet has also upgraded their Air/Fuel box to a two input design, and these systems can be daisy chained for monitoring multiple inputs. For XLC dyno models the brake controller has also been upgraded to include an internal temperature sensor, and a more responsive 16 tab tooth pickup.”Overall thew Dynoware RT is better hardware and software than what we had before with the EX version,” says Dynojet’s Carl Chastain.

Software that Shines

We talked with Dynojet Executive Vice President Dan Hourigan about the new PowerCore software WinPEP 8 dyno control, and WinPEP 8 data that offers an array of new features and functionality for dyno owners. “With the new software we can load up to twelve runs at a time, that have up to 32 channels per run, and then do analysis or comparison between each run.” says Hourigan.

The data side of the software displays information in the typical trace view, but it can also be viewed in 3D and table configurations. Hourigan says the alternative views like the table configuration is especially useful for tuners who can compare data from what the vehicle’s computer is requesting or commanding, and what is actually occurring with the car being tuned. “The 3D function would be useful for a variety of things including looking at a VE table and looking for the dips and anomalies, or transitions that may need to be focused on in the tuning,” he added.

Wireless

DynoWare RT also features ethernet connections for wireless communication rather than USB. “The reason why we chose ethernet is it’s terribly reliable, it’s somewhat immune to RFI and EMI interference, and all the dyno network is up in the air. You can actually connect to your dyno, and do everything you can when plugged in, but wirelessly. So you can be in the car, or outside the car in the dynocell and not have wires running into the vehicle or along the floor, etc.,” Hourigan says.

Another main factor in choosing ethernet connectivity according to Hourigan is the amount of data the DynoWare RT electronics is able to communicate back from the dyno. “This thing’s capturing data at such a higher rate relative to the old electronics that we had, that it became imperative that we increased our band-width by about 10 times,” says Hourigan.

This influx of data is due to the design of the new DynoWare RT package. The prior generation EX series electronics had one pickup tab, allowing the system to pickup one data point from the dyno per revolution. DynoWare RT picks up 32 data points per revolution via the 16 tab sensor, which has 32 windows for reporting back information. According to Hourigan this allows for extremely high resolution data.

New Control Interface

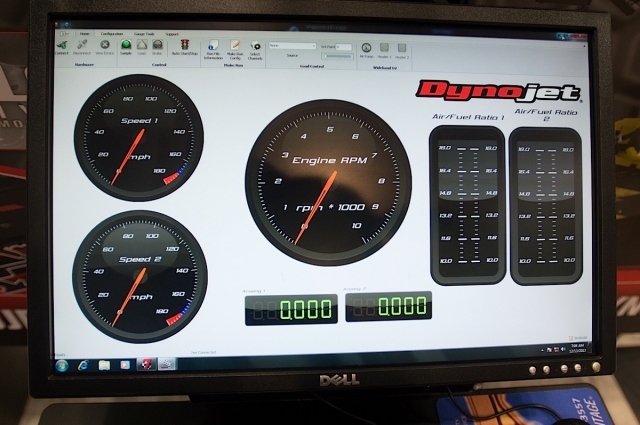

The last facet of the PowerCore software we’ll discuss here is the new display for dyno operation. Similar to a dash, operators can set up a number of dyno “gauges” and display them on screen as an analog or digital representation in a variety of configurations. This allows tuners and operators to monitor a variety of dyno inputs, all at once including third party, non-Dynojet info, and even data from an OBD II port on the vehicle.

There’s too many cool new features of the DynoWare RT electronics package, PowerCore software, and WinPEP 8 for us to list here. Be sure to watch the video, and check out Dynojet’s web site. This new equipment will be shipping with new dynos in 2014, and available as an upgrade for existing models as well.