One of the perks with holding down a position here at StangTV is that we get to see all sorts of inside information that we’re then tasked with bringing to you, our faithful readers. This time around, we were invited to see what goes into creating one of Ford Racing‘s Cobra Jet engines, with photography and an inside look through what goes into creating the heart of one of the most successful “factory” racing programs around. Although the Cobra Jet program doesn’t provide free racecars to anyone, if you’re lucky enough (and financially liquid enough) to get onto the build list, you’ll be receiving one of the most well-engineered platforms designed specifically for NHRA Stock and Super Stock racing that’s ever been constructed.

The Cobra Jet program came to light back in 2008, with the first cars rolling off the assembly line and virtually right into the winner’s circle in the hands of the Brent Hajek-owned, John Calvert-driven CJ at the 2009 NHRA Winternationals. Since then, the Cobra Jet has become the winningest late model in NHRA, including national event wins in 2009, 2010, 2011, and 2012, class wins at the 2011 U.S. Nationals, and a top ten finish with Bo Butner in Stock Eliminator in 2011. In addition, the Cobra Jet’s performance on-track had a big hand in Ford winning the 2011 NHRA Manufacturer’s Cup, as the national event win coupled up nicely with three runner-ups, four semi-final appearances, and 16 number-one-qualifier spots during the course of that season. Past versions of the Cobra Jet were outfitted with a 5.4-liter supercharged engine, but with the 5.0 returning to its rightful place between the fenders of the Mustang, the decision was made to outfit the factory race car with the current powerplant.

Keeping tolerances held in check is critical to the Cobra Jet engine program. Each part is measured in the climate-controlled engine building facility prior to installation to ensure durability in the demanding conditions these engines face.

Winning Formula

Naturally, when the gang from Ford Racing asked if we wanted to check out a build on the 2014 Cobra Jet 5.0L engine, we jumped at the opportunity to see what goes on behind the scenes at Ford Racing. The supercharged mill we followed features the latest and greatest in Coyote engine development, complete with a Ford Racing/Whipple 2.9L supercharger. The engine also uses the CNC port-matched manifold and cylinder heads in an effort to make the greatest amount of horsepower while remaining class-legal for NHRA Super Stock and other classes where the CJ competes.

Both Ford Racing and mainstream Ford engineers -best minds within the company, were all involved in the Cobra Jet program. When it came time to develop the Cobra Jet engine, the Ford Racing engineers realized that they already had a perfect base for the powerplant right under their noses – the 5.0L “Road Runner” engine that had been developed for the BOSS 302 variant of the Mustang. The BOSS 302 engine already wears the CNC-ported cylinder heads required to make big horsepower in the Cobra Jet. As the cylinder heads wear a pair of camshafts on each side, valvetrain development was one of the ways the Ford Racing engineers tried to boost horsepower further. In fact, after many hours of research time, it was determined that the 12mm-lift, 260-degree duration intake camshafts already installed in the BOSS would be the perfect complement, which simplifies the process. A new, 290-degree duration exhaust camshaft was profiled.

Top Left - Mahle supplies the pistons for the CJ engine, while connecting rods were sourced from Manley and are the same rod found in the 2003 Cobra, upgraded with ARP2000 capscrews. Top Right - The entire build process is detailed on this computer screen, giving the technician a step-by-step guide to assure each assembly operation is completed. Bottom Left - ATI supplied their Super Damper for the Cobra Jet engine. It drives the supercharger and keeps unwanted engine vibrations at bay. Bottom Right - Completed front dress including the TiVCT computer-controlled camshaft adjusters.

We saw a 60 ft-lbs torque increase at 4300 RPM just by optimizing the cam timing with TiVCT. – Jesse Kershaw, Ford Racing

Perfect Timing

One of the main developments within the 5.0L engine was the introduction of Ti-VCT, which is an adjustable camshaft timing system that’s computer-controlled and offers huge benefits in power, torque, and overall engine efficiency.

We spoke with Ford Racing’s Jesse Kershaw, who explained, “For us Ti-VCT is a way of life, included in many Ford engines. It allows significant gains for both horsepower and torque throughout the powerband. The 5.0L was designed to have it, so we use that capability. I wouldn’t consider it complex necessarily for Ford calibration but it does add more variables that require calibration time and attention. For the aftermarket it can be a major hurdle. Most aftermarket control modules simply lock out the cams for peak power which means they are left to make up for that power under the curve through other means.”

Bottom End

In 2013 Cobra Jet production included 47 supercharged cars and three naturally-aspirated machines. Each aluminum engine block undergoes strict machining processes at Livernois Motorsports before being shipped out to be completed at the Ford Racing facility. The naturally-aspirated engines are sleeved and machined to a 94mm bore size, while the supercharged variants keep the stock bore size of 92.2mm for strength and durability. Although the 5.0L engine was introduced with piston squirters in 2011, they have subsequently been phased out – piston squirters were also omitted from the start on BOSS and Cobra Jet engines.

Left - At the Ford Racing engine building facility, OEM technologies are used to assemble the engine, including the use of pre-calibrated pneumatic torque wrenches. Middle - One of the critical items to keep engine temperatures down is the intercooler, which resides under the supercharger. Right - A fully-dressed supercharged 5.0L Cobra Jet engine awaiting transfer to the Flat Rock facility for installation.

There were a number of other changes that made their way from R&D to the Cobra Jet engine as well. Kershaw said, “We had to upgrade the rods to Manley H-beams from the 2003 Cobra, with ARP2000 fasteners they will safely turn 8,100 RPM. We worked with Mahle to get the piston material, ring location, and weight that was deemed necessary to maintain consistency and durability. We also upgraded the oil pump to a billet gear unit that is tested at the OEM production facility and held to the tightest tolerances. While we have never had an oil pump failure, we added this as an extra margin of safety for our customers depending on what they plan to do.”

Another area where the Cobra Jet team saw increases in power came from the engine oiling system. According to Kershaw, removing as much windage as possible from the crankshaft netted them another twenty horsepower in the higher RPM ranges. Instead of developing a brand-new oil pan from scratch, they headed to the parts bin and selected the M-6675-M50BR oil pan kit from their road racing program, which helped to give much better oil control, as it implements a windage tray and an oversized oil pan with trap-doors installed to help manage oil flow. Although drag racing is a straight-line endeavor, the road race pan has been used successfully in this application.

Large gains were realized in the development of the 5.0L Cobra Jet via the use of this oil pan kit from the road racing program. The pan features trapdoors to keep the oil from sloshing around, while the windage tray pulls the oil away from the crankshaft during high-RPM operation.

Sucking Air And Blowing Boost

During the 2013 build process, the Ford Racing team put together three naturally-aspirated Cobra Jet packages for specific customers. Those naturally aspirated engines actually displaced 312 cubic inches thanks to the use of the big-bore 3.700-inch sleeves that were used in the block. Induction components include the Cobra Jet induction system including the Cobra Jet intake manifold that’s tuned for 7750RPM peak power, a set of CNC-ported cylinder heads, high-lift camshafts and a low-drag accessory drive.

The Cobra Jet manifold is a unique piece developed specifically for the naturally-aspirated 5.0L Coyote engine, and despite only showing up on three cars during the build process, the manifold will live on for years to come in the Ford Racing Performance Parts catalog thanks to the immense aftermarket support the Coyote engine has seen to date. The manifold is of composite construction and required the use of the Cobra Jet-specific oval-mouth throttle body on the production cars – aftermarket use of the manifold will permit the GT500 throttle body as well. Since this manifold fits every 5.0L Coyote engine out there, we suspect it’ll be the topper to a bunch of hardcore racing builds as time goes by.

Meanwhile, on the supercharged side of the equation, the blown version of the Cobra Jet wears the 10-rib Whipple/Ford Racing 2.9L Twin-Screw supercharger that includes a CNC-port-matched intake manifold and the same “Roadrunner” CNC-ported cylinder heads that appear on the naturally-aspirated version. Camshafts in both engine versions are a proprietary Ford Racing custom grind that has been developed to maximize the engine’s performance while taking advantage of the NHRA’s Stock Eliminator rulebook.

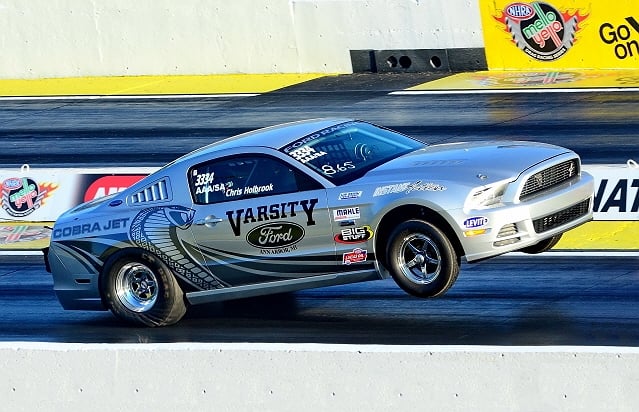

The Cobra Jet featuring the 5.0L engine has shown to be an incredibly impressive performer so far during the 2013 racing season, with the NMRA and NMCA both hosting Cobra Jet Showdown events. The NMRA’s Cobra Jet Showdown at Bradenton Motorsports Park earlier this year had Chris Holbrook finish in the runner-up position with his 2013 302 cubic-inch supercharged Cobra Jet with an awesome 8.51 at over 160 MPH. Holbrook has continued to terrorize the competition all year long no matter where he goes, using the data gained on the track to become the “quickest production vehicle in factory trim” earlier this year, and Holbrook has been setting records all season long in the same vehicle.

Getting Calibrated

Big changes were also in store in the engine management department, as the 5.0L engine uses a completely different processor than the previous year’s 5.4L engine. There was a steep learning curve for calibration, but much of the development work had already been completed through the use of a number of different Ford Racing test cars.

Kershaw explained the calibration process to us. “The 5.0 uses a completely different PCM than the prior year 5.4L Cobra Jets, so there was definitely a change necessary. However, because we lead the industry with our calibration for street Mustangs we were able to implement software and calibration from our Mustang GT supercharger kit, as well as utilize our proprietary TracKey calibration and software from the BOSS 302. Beyond that we had some experience already with racing the 5.0L in our turn-key road racing BOSS 302R and BOSS 302S models. This doesn’t take away from the hundreds of hours devoted to the Cobra Jet calibration specifically, just that we have a total approach to our racing programs and we can build upon that every year.”

Unfortunately, during the course of putting this article together, twenty-year Ford veteran, Ford Racing Powertrain Supervisor and gearhead-deluxe Rob Deneweth suddenly passed away, negating our opportunity to pick his brain about some of the decisions made during the course of outfitting the CJ with its particular bits and pieces. Deneweth was one of the driving forces behind the Cobra Jet program and the most recent Twin Turbo Cobra Jet project that debuted at SEMA in 2012, and his passing is felt every day. “All of us at Ford Racing are deeply saddened by the passing of our colleague and friend Rob Deneweth,” said Jamie Allison, director, Ford Racing. “Those of us at Ford involved in the racing program are very much like a small family, and when you lose a member of your family, you grieve and feel a real loss. Rob was a terrific engineer who did such great work, including his effort with the most recent Twin Turbo Cobra Jet project. All of us at Ford Racing send our deepest condolences to Rob’s wife, Julie, and their three children. We have lost a true friend.”

Despite the fact that Rob is no longer with us, his efforts will be seen and heard for years to come in the Cobra Jet program. Even though the car is limited to only around 50 lucky buyers every year, the Cobra Jet vision is years out. Kershaw says, “We absolutely have a long-term vision for the Cobra Jet program. It’s part of a larger world-wide strategy for production-based racing, so we do have plans roughed in over many years. Like any program there are milestones and checkpoints to ensure our goals are unchanged and we can still deliver. Factors such as changing rules and customer feedback can change the program direction until final approval. We are continually striving for improvement! When building a minimum of 50 cars in a relatively short window takes months of planning and preparation to make sure we are capable of delivering to the customer in a timely manner.”

As we have been to the Flat Rock plant where the Cobra Jet is built, we’ve seen firsthand just what a labor of love the Cobra Jet program is, and thank those at Ford Racing who go the extra mile to provide those of us lucky enough to plunk down the coin with an awesome factory-built engine and race car.