In a recent update on our Project 666 Fox-body Ford Mustang from here at the powerTV garage, we provided a general look at and installation of a whole set of new high performance drivetrain components from TCI Automotive, including an 8-inch Pro-X torque converter, an Outlaw shifter, flexplate, and other go-fast parts to make our ride really tick. But, at the heart of it all is TCI’s C4 automatic transmission, which is based on the original and popular OEM C4 transmission produced by Ford Motor Company for more than two decades. The race-intended TCI C4 improves upon the reliability and durability that the C4 has long been known for, which is just what we’re looking for to mate with our naturally-aspirated, 408-inch Windsor motor producing nearly 575 horsepower. We just know that our fox body had some 10’s in it, and with a previous best of 11.91 at just over a buck-20, we’re definitely in the hunt for much lower numbers.

In this installment on Project 666, we’ll take a more in-depth look at the venerable C4 that TCI has redesigned with the power-user in mind, along with the installation of the transmission, torque converter and other related components. As well, the moment we’ve all been waiting for finally comes, as 666 hits the track in Fontana with some impressive results.

Built Ford Tough

Ford’s longstanding C4 three-speed automatic transmission went into production in 1964 and was the first all-Ford designed and manufactured automatic transmission. And when it comes to strength, the 1970 and newer C4’s are the way to go with their large input shaft. The 26-spline and .839-inch shaft make for a unit that can handle a lot of punishment; sometimes upwards of 600 horsepower when utilizing hardened, aftermarket input shafts and splines. In addition, the cases made after 1970 use a different mounting design from previous versions as the bellhousing bolts up to the case rather than the front pump, equating to an additional level of strength for demanding applications.

The C4 underwent several refinements around 1970 while being employed in a long list of Ford, Lincoln, and Mercury vehicles, and to this day is still the simplest and most reliable automatic transmission that Ford has ever produced.

Despite the end of it's production, however, the C4 remains popular with the drag racing and hot rodding communities for it's simplicity and durability, and remains a popular choice today by a multitude of later model Mustang drag racers.

Ford’s C4 was replaced in 1982 by the C5, and despite the end of it’s production, remains popular with the drag racing and hot rodding communities for it’s simplicity and durability. In fact, a multitude of late-model Mustang racers even choose the C4 over GM’s venerable two-speed Power Glide for racing purposes. And so it should come as no surprise why we opted for TCI’s improved and enhanced version of the C4 to help propel our Project 666 Mustang.

Taking The C4 One Step Further

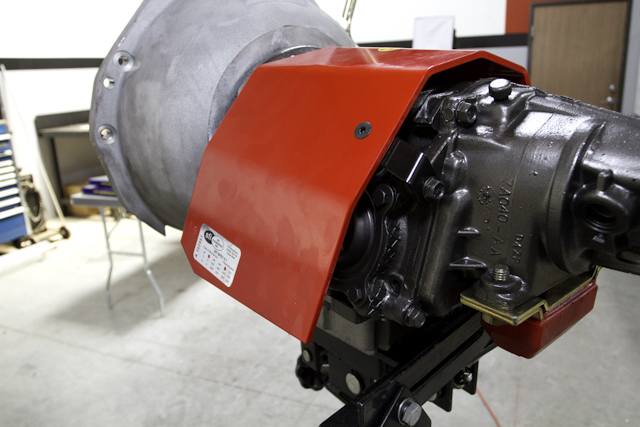

The external transbrake solenoid and bracket are installed on the transmission. By being installed outside of the transmission case, the solenoid is able to cool much quicker than an internal design when; something very important if you're a drag racer in a round-robin situation.

While the Ford C4 is widely regarded as an exceptional transmission with the utmost in durability, it is not, however, generally up to the task of handling a high amount of horsepower or standing the test of grueling racing applications. And that’s where TCI takes a great starting point with the Ford C4 transmission, and conformed their own internal design and components to make this one stellar racing transmission that’s used by racers far and wide.

TCI’s C4 is a standard transbrake, three-speed automatic transmission, sporting the low-drag, six-pinion planetary kit that still uses the stock ratio but has bearings all the way through. A late-model, 26-spline case filled setup, it also has a reinforced forward gear drum, a billet intermediate servo assembly, 300M input shaft, a deep aluminum pan, and Red Eagle clutches. It should be noted that these features are all standard equipment on this model transmission.

The planetary set sports bearings all the way through, decreasing the amount of drag that ultimately robs your engine of horsepower.

This transmission is based upon a factory C4 transmission case, and designed and intended for use in racing applications. “This particular transmission, with many of the features that is incorporates, isn’t something that we’d suggest be driven on the street. It could be done periodically, but it isn’t something you’d want to put in a vehicle that you’re going to drive often,” said Scott Miller of TCI.

The low-drag, six-pinion planetary set is installed in the transmission case. The use of bearings in the gear set creates less drag than the thrust washer design used in the factory C4 transmissions.

The planetary set, which as mentioned, sports bearings all the way through, helps to cut down on drag that robs valuable horsepower; something that is always crucial in keeping at a minimum after spending thousands of dollars to create said horsepower, only to give it away. Explained Miller, “Ford transmissions – the C4 and C6 – are both real power robbers. They draw a lot of horsepower from the motor because the planetaries are heavier and run on thrust washers all the way through. So that creates more drag, pulling horsepower from the motor.”

The C4 – TCI’s Way

TCI has given the internal components of the C4 a complete overhaul, creating a design that promotes less drag and increased durability.

The design that TCI has implemented decreases the amount of drag considerably, pulling in the neighborhood of 18-20 horsepower, down from what is commonly around 30 horsepower in high gear. And being a Ford transmission where it would be commonplace to find it bolted behind a small block engine that on the average doesn’t typically make large amounts of excess horsepower, that 10-12 horsepower becomes quite a difference.

The six-pinion planetaries are created entirely in-house by modifying the factory gear assemblies to add in the extra gears. From the factory, the C4 sports a three-pinion planetary, and thus, is doubled through TCI’s process. The three-pinion planetary setup in the factory transmission is notoriously a weak link, and by increasing it’s size, the overall strength of the planetary assembly is vastly improved.

The deep, crafted aluminum pan outfitted underneath the TCI C4 holds an extra quart of fluid as compared to the factory unit, preventing the chance of fluid starvation, especially in high-RPM applications. The thick, aluminum construction is also much tougher than the OEM pan.

The deep, crafted aluminum pan outfitted underneath the TCI C4 holds an extra quart of fluid as compared to the factory unit, preventing the chance of fluid starvation, especially in high-RPM applications. This is a very common occurrence in higher RPM engine combinations, where the fluid cannot be pumped quick enough to get it back into the pan quick enough to keep the filter submerged in the fluid. And in being constructed with strong, thick, aluminum, it provides some additional strength and rigidity to the case.

The pro-tree style valve body in the C4 uses a reverse pattern setup with an external solenoid, meaning the transbrake must be engaged in reverse in order for the car to back up.

The transbrake valve body is designed and manufactured in-house at TCI and is a pro-tree style unit that uses a reverse pattern setup with an external solenoid. A “pro-tree” valve body means that the transbrake must be engaged in reverse in order for the car to back up.

The entire TCI C4 transmission, like every product that TCI manufactures, goes through a rigorous testing procedure to check for quality and function. This process is done in three separate stages. First, the valve body goes through it’s own special dynamometer, the transmission is then hydraulically tested on another dyno, and finally, the valve body is bolted on and pan installed and the entire unit is put through its paces on yet another dyno that returns results with figures such as the pressures for each gear, the cooler flow in each gear, and other detailed information.

700 Horsepower? No Problem

These improved elements of the trusty C4 by TCI make this a very solid unit for use in higher horsepower applications, and a great fit for our Project 666 Mustang. “This transmission could be put behind a 750 horsepower application with no problems whatsoever. As well, there are some custom things that we could do to increase the pressures to make it handle even more horsepower, if needed. Part-wise, it’s just fine, but when you’re increasing the horsepower, it’s a good idea to bump the line pressure up a little bit more,” says Miller.

In addition to the C4 transmission itself, we will be outfitting our Project 666 with a host of other add-on accessories from TCI to get the best performance and ease of use out of our new drivetrain.

Rounding Out 666’s Driveline

The TCI Transmission Cooler kit is designed specifically for racing applications and is the largest that TCI offers.

First, we have the C4 SFI-certified bell housing, made of a tough 6061 alloy aluminum that will bolt right up to the C4 without any modifications. The C4 transmission doesn’t typically come with a bellhousing included in the kit, because as a detachable component, most people commonly have their own. The bellhousing, along with the Transmission Cooler Kit (Part# 823800) come highly suggested by TCI, but not a mandatory add-on. The Performance Cooler is a 26,000 GVW cooler designed specifically for racing applications, and is the largest that TCI manufactures and it outfitted with a #6 AN female fitting on it.

Unlike other flexplates on the market that have the ring gear welded on one side, TCI has taken the extra step of performing the welds on both sides of this thicker-than-stock piece.

TCI’s SFI-approved flexplate features extra welds all the way around both sides. Most flexplates on the market have the ring gear that is welded on one side, but TCI has taken the extra step of performing the welds on both sides of this thicker-than-stock piece. 666 will also benefit from the use of a RollStop Solenoid (Part number 861100) to perform burnouts like the professionals. By using the RollStop, you simply pump up the brake pressure, apply the RollStop, and release the brake pedal, which keeps the front brakes applied during the burnout procedure. According to Miller, this unit is universally designed to work with ay type of breaking system, and can withstand pressures of 3,000 psi while only drawing one amp of current.

For our purposes, we chose TCI's Outlaw Shifter that features an integrated two-button handle: one for the transbrake and the other for the line lock.

TCI offers a handful of options for shifters that all comes down to personal preference, and we chose to go with the Outlaw Shifter that features an integrated two-button handle: one for the transbrake and the other for the line lock. For those that prefer to do without the button setup, an Outlaw Shifter minus that feature is also available. Along with the shifter, we’ll be utilizing TCI’s three-speed Rev Pattern Thunder Stick/Outlaw Gate Plate that essentially makes the Outlaw Shifter a reverse pattern setup for the C4 transmission, which uses a reverse pattern valve body.

We’ll be outfitting our C4 with TCI’s SFI-approved Trans-Shield, made from 6061 aluminum that bolts right up without any modifications. Also, we’ll be running our C4 with TCI’s Max Shift ATF fluid, which is available in four different blends to cover most automatic transmissions. Said Miller “it’s not a Dextron-based fluid, but it has additives in it that makes it run a lot cooler than other fluids without breaking down as quickly and easily.”

Converting The C4

Our C4 will be mated up to TCI's eight-inch, steel stator, weld-together C4 converter designed for full race applications, which is good for about 875 to 900 horsepower

And finally, our drivetrain would be virtually useless without a high performance torque converter mated to the C4 transmission to transfer the power to the rear tires. And so we’ve installed TCI’s eight-inch, steel stator, weld-together converter. This converter is designed for full race applications that Miller states is good for a maximum of about 875 to 900 horsepower, as it will stall too high with any more horsepower than that.

Nowadays, racers are going with much larger converters, such as the 9 and 10-inch Pro-X line, because of the amount of horsepower they’re producing. However, for a combination such as ours, the smaller converter is a perfect fit for the level of horsepower that we’re planning to produce, as a larger model would simply bottleneck our engine on the racetrack. Said Miller, “In this type of application, the eight-inch converter is going to perform better, because with the higher horsepower rated converter, it’s going to slip too much on the top end, cutting down on elapsed time and mile per hour.”

TCI redesigned C4, outfitted with stronger and higher performing components from front to back provides the peace of mind that transmission troubles should be the least of our worries with Project 666.

Trip to Fontana with High 10s on the Mind

Our trip to the track began surprising early, with a departure time of six o’clock in the morning, in order to arrive at the track in time for a prime pit spot. As it turned out, we ended up a 1/4 mile from the staging area. We used the two mile asphalt circle track that is parallel to the pit area as a point of reference in measuring the distance. This is the same oval track that NASCAR holds their annual Fontana races on.

A quick check of fluids, tire pressures and window cleaning, and we were set. No sooner than we got James stuffed into the driver’s seat, the call came over the public address system for cars to start moving to the staging area.

Our initial choice to enter in the Sportsman class turned out to be a mistake and we chose to move up into the Pro class. On the first run we left at 3,500 RPM of the trans brake, and our project car rebounded with a 1.49 sixty foot and a 7.17 @ 94.23 mph eighth mile where he lifted and coasted out the rest of the track to a 11.92 @ 87.93 mph. James reported an issue with the shifter possibly being mis-adjusted. One the second pass of the day, 666 carried the wheels with a 1.43 sixty foot and a 7.06 @ 94.35 mph eighth mile time and rounded out the quarter mile with a 11.17 @ 117.70 mph pass. We did notice during the run, each gear change resulted in a loud bang through the exhaust system.

Another five minute walk back to the trailer and our worst fears were confirmed. The pop in the exhaust was substantial and we needed to track down the source. After listening to the engine, we determined that there was a problem with an leaky exhaust gasket that was drawing fresh air into the exhaust flow.

Another five minute walk to the staging area where we met James waiting to move into the burnout box. James drew the left hand lane, where he started on the first run of the day. The car launched much harder than the previous runs and the gears shifted smoothly resulting in a breakout run. We had dialed a 10.80 and ran a 10.56 @ 116.94 mph while on the rev limiter the last 150 feet, due to the lack of rear gear. With the proper gearing and being able to stay in it the entire duration of the track, 10.30s would have been achieved. The last five minute walk was a bitter sweet feeling because of the nice run but the reality of breaking out and going home meant the end of the day.

Our three time slips throughout the day with car number 7555. Click the picture above for a larger version.

Because our plan for this project was to take the route of an automatic transmission, one of our primary needs and objectives was outfitting the car with a transmission that we knew would stand up to the demands of the horsepower from our venerable 408, and TCI’s C4 is exactly that.

It combines all the great attributes that Ford fanatics have come to know and love, with the increased durability and performance that has made TCI among the leaders in the industry. And coupled with other quality driveline components from their catalog, we rested assured that once we hit the track, transmission troubles would be the least of our worries. With plenty more performance on the table, we’re not quite done with this Fox just yet, so keep it here for more updates as we pound the quarter mile in our pursuit of the mid nine-second zone.